Top CNC Milling Services In New Jersey

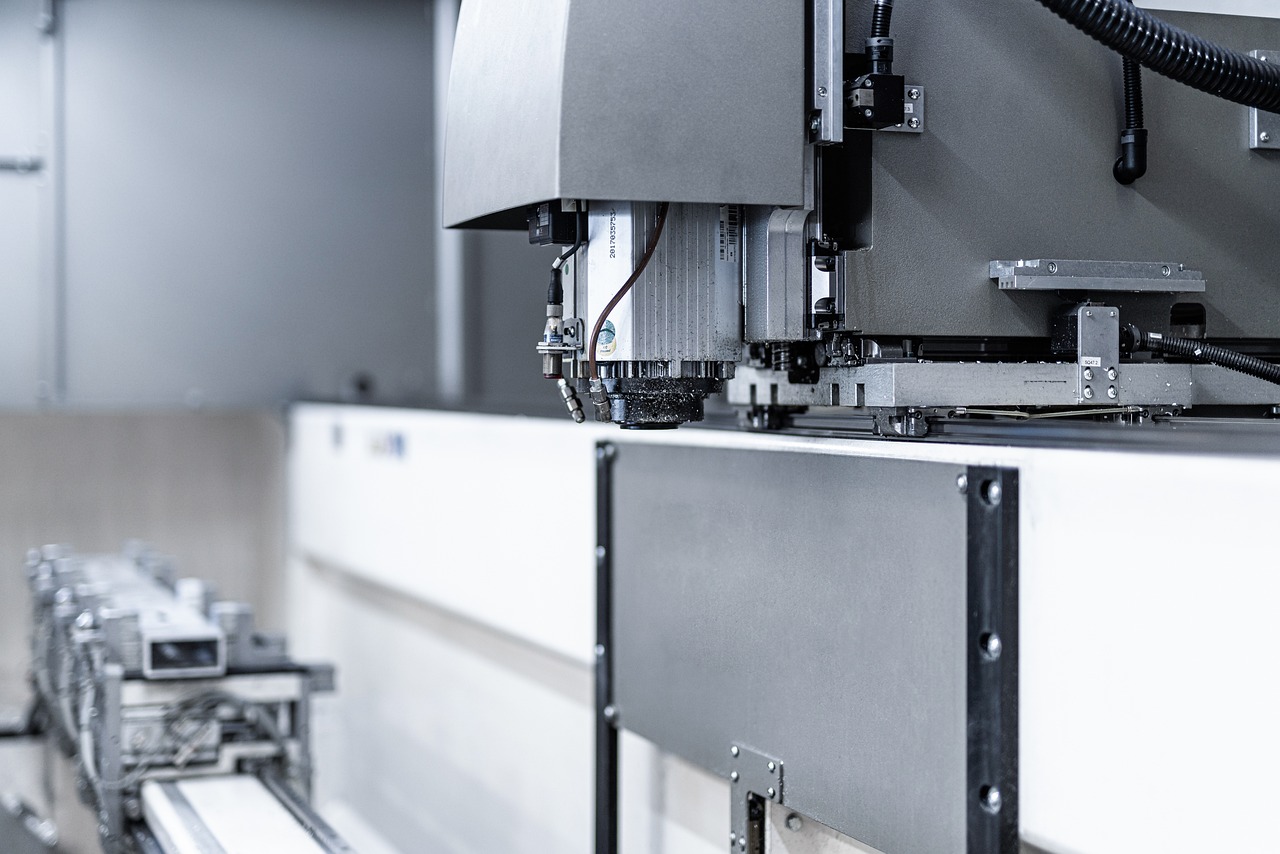

As full-service metal fabricators, we handle each aspect of metal fabrication and finishing. This includes CNC machine lathing and milling services. We put every second of experience over decades in the industry into each production run.

This lets us identify design flaws long before we enter the production phase and adjust accordingly. We have used our precise CNC mills to service many industries from aerospace and defense to automotive and medical. Our CNC milling services are only as effective as they are because of our ironclad process that has served us and our customers for decades.

A Tried and True Milling Process

At DureX, we pair the automated capabilities of powerful CNC mills with our team’s ingenuity. This lets us focus on quality control at every stage of our full-scale productions. That said, none of this is possible without a thorough design phase to kick things off.

Design

Design is the first part of our CNC milling process, and it lays the foundation. Our skilled design team can draft designs based on your specifications and desires. We can also work using your designs and change them as needed to ensure a precise, smooth milling process.

Our team must make sure the geometry and design are compatible with our machine’s axes. Otherwise, the mill cannot shape the materials to the desired shape during production. This is one of the last things we check before we translate the design into code.

Fabrication Processes

Programming

While our machines are essential, the way we program them is vital to the milling process. The process isn’t as simple as inputting dimensions. Instead, we translate your designs into a code that our machines can act on.

This code determines the speed and movement of the machine to ensure precision. Quality control starts during the design phase and continues during programming before milling begins. We carefully craft the code and check to make sure the machines reflect it before proceeding.

Production

While the automated nature of CNC milling is impressive, we still put a human touch on each production run. Our machinists are always careful to inspect, set up, and adjust the machines to ensure an effective operation. We use this time to make sure everything is aligned, secured, and level.

This also serves as a final chance to check the code before starting production. The CNC milling process is quite fast, precise, and efficient. Such fast results let us double-check for quality and move on to the finishing and final quality assurance phases. It also comes in handy for large production runs.

We Work With Many Materials

At DureX, we use many common manufacturing materials in our milling process. These include steel, aluminum, copper, and brass. Such materials are ideal for milling because of their texture, consistency, and density.

That said, we don’t use soft materials like silicone and rubber for milling. Other materials, such as ceramic, are too hard for our machines, so we exclude them to avoid damage. We source the best materials we can find as that is the only way to wind up with high-quality parts and products.

Why Choose DureX

Precise and Reliable CNC Mills

Our milling process is only as great as our CNC mills, and we don’t take that lightly. Each of our well-maintained CNC mills is set up to automatically exchange tools during production. This eliminates the need for pauses during production and ensures fast results.

Boundless Experience

With decades of experience, we have watched the world of CNC machining and milling grow firsthand. This experience goes into each step from design and programming to production and quality assurance. Our experience with CNC mills, many materials, and diverse designs helps minimize troubleshooting and save time.

Fast Production

At DureX, our machinists can produce simple parts in hours using our CNC mills. Bigger, more complex parts take longer, but we waste no time. Such a fast production speed lets us put as much time into design, programming, and quality assurance as possible. This is endlessly helpful for small and large production runs alike on any timeframe.

Unparalleled Complexity

CNC mills afford us the chance to work with complex geometry and designs. However, that’s only possible with the drive and vision that our designers, programmers, and machinists provide. We can translate your vision and design into a flawless part or product that is only possible through CNC milling.

Full-Scale Production

As a full-scale production facility, we handle all aspects of production at DureX. Not only does this save our customers time and money, but it maximizes quality. Not only do we specialize in CNC milling and machining, but we also offer finishing services.

Our eco-friendly finishing process ensures your parts are clean and well-coated. We use a 5-stage degreaser and washer system to clean and prepare parts for powder coating. This tried and true system helps us powder coat thousands of parts hourly, which is essential for big production runs.

Precise Milling Services for Any Industry

The industries we serve at DureX are just as diverse as our in-house capabilities. Our array of milling, machining, and finishing equipment lets us cater to many industries. Some of the many industries we serve include:

- Power and Energy Generation

- Healthcare and Medical Devices

- Transportation and Automotive

- Industrial Machines

- Aerospace and Defense

We cater our designs, specifications, and compliance checklists to the industry we serve. This lets us ensure your custom parts are compliant and certifiable.

Dependable CNC Milling Services in New Jersey

CNC milling may be largely automated, but it’s only as effective as the team that’s behind it. Everyone from our designers and machinists to our quality assurance team is detail-oriented and precise. We leave nothing to chance, and we work the kinks out long before we enter production. Call DureX at (908) 688-0800 and ask about our CNC milling services.