Expert Metal Fabrication for Any Application

At DureX Inc., we understand that choosing the right metal fabrication method isn’t just a technical decision—it directly impacts your production cost, lead times, and product quality. Whether you’re launching a new product or scaling up an existing line, selecting between CNC machining vs stamping can make or break your success.

With over 75 years of experience, DureX has been a trusted partner to manufacturers across New Jersey and the East Coast. From low-volume prototyping to high-volume production, we offer both precision CNC machining and cost-effective metal stamping under one roof—right here in Union, NJ.

If you’re comparing metal fabrication processes and wondering which is the best fit for your next project, our team of engineers is here to help you make the right call.

CNC Machining vs Stamping: A Comparison of Capabilities

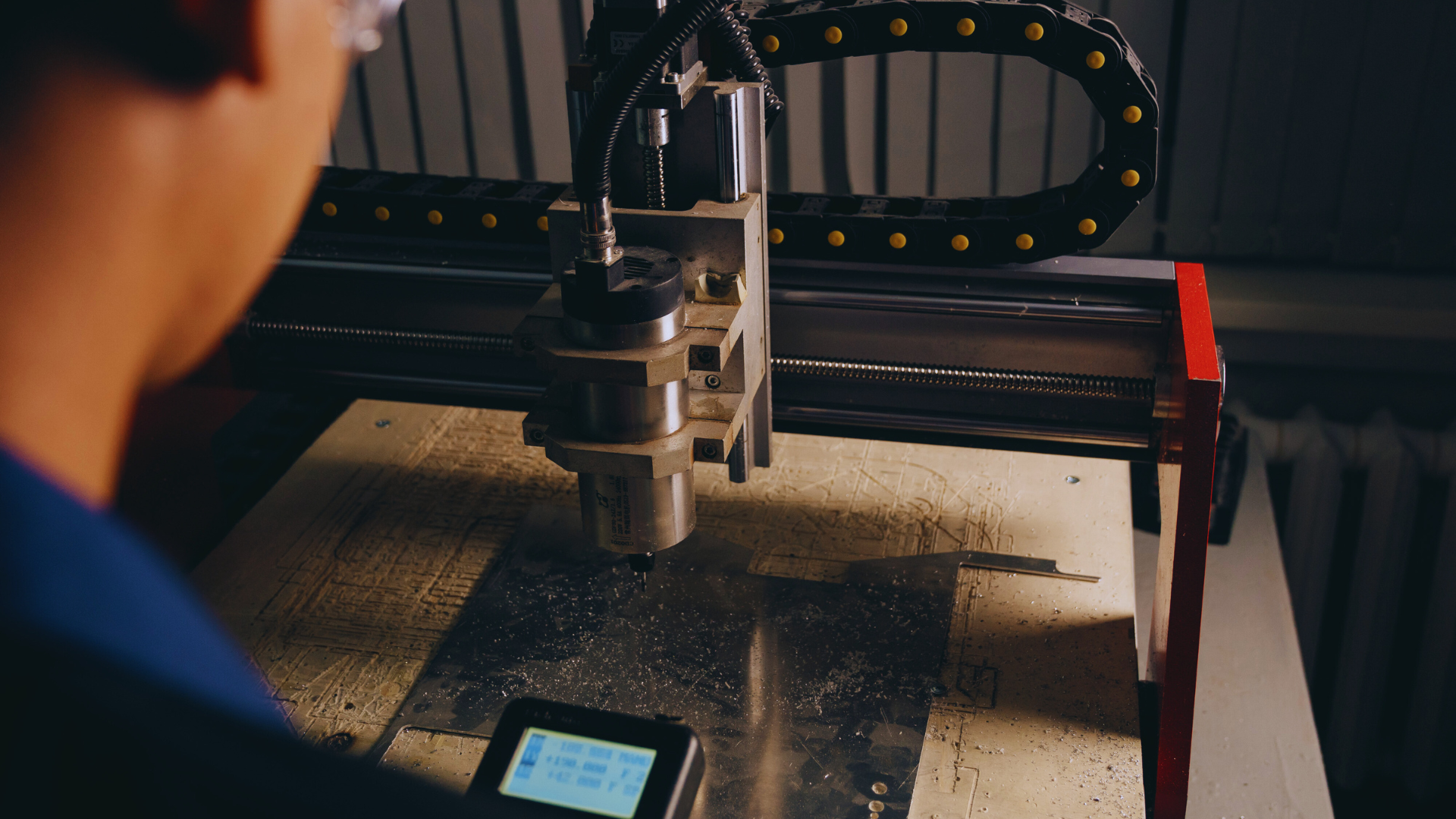

Our CNC machining services are built for precision, flexibility, and reliability. CNC—short for Computer Numerical Control—uses computer software to guide cutting tools that remove material from a solid block, producing exact shapes down to the finest detail.

The operations are determined by a computer program, which defines the final geometry and machining steps. A CNC machine executes these instructions, allowing for precise shaping and control over multiple axes. This process is ideal for projects requiring tight tolerances, complex geometries, and high precision.

At DureX, our CNC department operates with advanced multi-axis machines capable of handling hard metals, thick materials, and small-to-medium production runs. Whether you’re machining turbine blades, medical devices, or custom engine components, we provide the accuracy needed for even the most demanding applications.

Thanks to our Union, NJ-based facility, local clients benefit from reduced lead times and hands-on communication. We’ve supported manufacturers throughout New Jersey, New York, and Pennsylvania with one-off prototypes, R&D parts, and short-run precision parts—all without the delays or guesswork that come with outsourcing. Creating prototypes quickly is essential for facilitating design iteration and testing, helping you move from concept to production faster.

Our CNC capabilities are perfect for:

Complex, non-repetitive parts

Low-to-medium volume jobs

Projects that require multiple revisions

High-performance components where failure isn’t an option

When precision matters, CNC machining gives you control and confidence.

Metal Stamping Services

For high-speed, high-volume manufacturing, metal stamping remains one of the most cost-effective and efficient fabrication methods available. It is also highly efficient for mass production. At DureX, we specialize in metal stamping for clients who need large quantities of consistent, accurately formed parts—without sacrificing quality.

Using high-tonnage stamping presses, precision dies, and decades of experience, we shape metal sheet into both 2D and 3D forms. A stamping press is used to mechanically shape the metal sheet into parts. Our process covers all key stamping operations including blanking, bending, forming, and coining. Once your tooling is set, we can run parts continuously—the stamping process can run continuously for high-volume production—to meet demanding schedules and tight deadlines.

Located in Union, New Jersey, our facility is equipped to support manufacturers across the Tri-State Area, helping you reduce shipping time, lower freight costs, and maintain greater control over your supply chain. Our in-house tooling and press capabilities make it easy to go from prototype to production without changing vendors.

Metal stamping is ideal when you need:

Mass production of the same part

Thin metal materials like stainless steel or aluminum

Fast turnaround and low cost per unit

Long-term consistency with minimal variation

Stamped parts are well-suited for high-volume, consistent production, though they may have limitations in achieving complex geometries and sometimes require secondary machining for tight tolerances.

If your project involves thin materials and needs to scale quickly, our metal stamping solutions deliver both speed and savings.

Comparing CNC Machining vs. Metal Stamping

When it comes to selecting the right manufacturing process, there’s no one-size-fits-all answer. CNC machining and metal stamping are different processes, each suited to specific needs and applications.

Each method offers unique advantages depending on the project, such as high precision or high-volume efficiency. Both processes also provide unique benefits—CNC machining offers flexibility and customization, while metal stamping excels in speed and cost-effectiveness for large runs.

The decision between CNC machining vs metal stamping depends on your part geometry, volume, timeline, and budget. At DureX, we don’t push one method over the other—we help you make the smartest call for your business.

Here’s a breakdown of how these two methods compare:

Feature | CNC Machining | Metal Stamping |

|---|---|---|

Precision | Extremely high; ideal for tight tolerances and achieving specific dimensions | Good; best for parts with standard tolerances and can also achieve specific dimensions |

Part Complexity | Handles intricate, custom geometries and required shape | Best for repeatable, simpler forms and required shape |

Material Thickness | Great for thick and hard metals | Best for thin sheets |

Production Volume | Low to medium volumes, prototyping; may have higher cost per unit for large volumes due to equipment and setup | High-volume, long-run manufacturing; can produce multiple parts in a single cycle, increasing efficiency |

Setup & Tooling Cost | Lower initial investment | Higher upfront die/tooling cost, but lower cost per part |

Material Waste | Generates more waste (subtractive process) | Very efficient with minimal material waste |

Flexibility | Ideal for revisions and short timelines | Less flexible once tooling is finalized |

Process Steps | May involve multiple steps for complex or custom parts | Often involves multiple steps, especially for custom or complex parts |

Final Product | Accuracy and features of the final product depend on programming and process selection | Final product’s accuracy and features depend on die design and stamping process |

Both CNC machining and metal stamping are designed to achieve the required shape and specific dimensions for your application, but the approach and tolerances may differ. Metal stamping can efficiently produce multiple parts in a single cycle, while CNC machining is ideal for custom, complex parts that may require multiple steps.

Keep in mind that CNC machining may have a higher cost per unit for large volumes due to equipment complexity and setup, but it offers unique advantages in flexibility and precision. The final product’s accuracy, features, and cost will depend on the process you choose.

Need help determining the right method? Our team in Union, NJ, will evaluate your specs and guide you through the most cost-effective path—no guesswork, no overspending.

Additive & Hybrid Manufacturing Integration

While CNC machining and metal stamping dominate traditional metal fabrication, modern production often benefits from hybrid approaches and additive manufacturing (AM). At DureX, we use these complementary methods to optimize cost, lead time, and performance—especially during early-stage development or complex production cycles.

Additive manufacturing, commonly known as 3D printing, enables us to build complex geometries layer by layer with minimal material waste. Unlike traditional manufacturing, which often requires multiple machines for different processes such as milling, turning, and drilling, additive manufacturing can consolidate these steps into a single process.

This is ideal for rapid prototyping, tooling development, or low-volume production runs of custom parts where traditional methods might be too costly or slow. For example, creating mock-ups of turbine blades, engine housings, or electrical enclosures can be done quickly and iteratively before committing to full-scale production.

In many cases, we also implement hybrid manufacturing, where we combine soft tooling, laser cutting, or turret punching with selective forming or CNC finishing. These multi-step processes allow us to:

Keep initial tooling costs low

Meet tight deadlines

Maintain quality across multiple stages

By integrating AM and hybrid methods with traditional sheet metal, machining, and stamping processes—where ‘stamping’ is an umbrella term that includes techniques like blanking, drawing, and piercing—DureX provides flexibility and agility that few other fabricators can match.

We help clients in New Jersey, New York, and the Northeast take advantage of these innovations to reduce production costs and shorten lead times, without compromising quality.

DureX’s Approach to Metal Fabrication

At DureX, we don’t just provide metal fabrication services—we partner with our clients to engineer the most cost-effective, scalable, and reliable manufacturing solutions available.

We help clients choose the best process for producing custom metal parts for their specific applications, ensuring optimal results. Whether you’re deciding between CNC machining vs stamping, or exploring hybrid or additive options, our team brings deep experience and technical insight to every project.

Located in Union, NJ, our 120,000 sq. ft. facility is equipped with:

Over 50 stamping presses (up to 400 tons)

AMADA CNC laser and turret punch presses

Automated press brakes and robotic bending systems

In-house finishing, including powder coating and assembly

We offer both rapid prototyping and high-volume production, allowing you to grow with one trusted vendor instead of juggling multiple suppliers. For startup companies, we help avoid heavy upfront tooling investments with soft tooling or CNC solutions. As volume scales, we support a seamless transition to metal stamping using progressive dies or staged tooling.

Our engineers work side by side with your team to optimize:

Material usage and part design

Manufacturing process selection

Tooling and setup efficiencies

Lead time and cost reduction

With customers across New Jersey, New York, Connecticut, and Pennsylvania, DureX has earned a reputation for precision, integrity, and speed. Whether you’re producing engine parts, medical housings, HVAC enclosures, or electronic frames, we tailor the process to fit your goals, not the other way around.

Applications Across Industries

DureX Inc. serves a wide range of industries where precision, scalability, and efficiency are non-negotiable. By offering both CNC machining and metal stamping—along with sheet metal fabrication, forming, and value-added services—we meet the complex needs of manufacturers across the Northeast and beyond.

Here’s how different industries benefit from our fabrication solutions:

Aerospace

CNC machining for tight-tolerance components like brackets, housings, and internal systems

Hybrid methods to reduce weight and optimize strength

Certified quality control to meet aerospace compliance standards

Medical & Life Sciences

Precision parts for diagnostic equipment, enclosures, and specialized tooling

High repeatability for production runs of consistent quality

CNC processing of hard metals and sterile-grade materials

HVAC & Building Systems

Stamped sheet metal enclosures, frames, and panels

Knockdown designs to minimize shipping and storage costs

Local support for contractors and OEMs throughout New Jersey and NYC

Electronics & Telecom

CNC-cut panels, racks, and connectors with exact cutouts for wiring and interface

Stamping for lightweight, repetitive components at scale

Industrial Equipment

Engine parts, chassis, and support structures built from a mix of CNC, stamping, and laser cutting

Prototyping support for product development teams looking to test and validate designs

With every project, we focus on fit, function, and manufacturability—not just getting the part out the door. Our experience across industries helps us spot opportunities to reduce cost, eliminate waste, and improve turnaround time.

Why Choose DureX

When it comes to metal fabrication, precision is only part of the equation. At DureX, we combine advanced technology with decades of hands-on experience to deliver more than just parts—we deliver confidence, consistency, and competitive advantage.

All-In-One Facility in Union, NJ

We house metal stamping, CNC machining, laser cutting, turret punching, bending, powder coating, and assembly under one roof. This centralized model streamlines your supply chain, speeds up production, and reduces the risk of errors that come from juggling multiple vendors.

Flexibility for Any Stage of Production

Whether you’re prototyping a new design or preparing for a full production run, our team will guide you through the best fabrication method—no upsells, no shortcuts. We help clients avoid high upfront investments when volumes are low and scale to high-volume metal stamping when the time is right.

Engineering Support That Saves You Time and Money

Our in-house engineering team works closely with yours to refine part design, select materials, and optimize manufacturing processes. We often suggest changes that improve performance, reduce waste, and lower production costs—without compromising on quality.

Reliable Turnaround and Direct Communication

Located right in Union, New Jersey, we’re easy to reach, responsive to your needs, and available for in-person collaboration. You won’t be dealing with overseas time zones, vague status updates, or costly delays.

Proven Track Record

From startups to Fortune 500 manufacturers, DureX is the fabrication partner of choice for companies that need precision, speed, and long-term dependability. Many of our clients have been with us for decades—and that’s not by accident.

Let’s Build Something Better

Choosing between CNC machining and metal stamping doesn’t have to be a guessing game. At DureX, we’ll walk you through your options based on what matters most—volume, precision, cost, and lead time—and help you select the method that gets the job done right.

Whether you’re prototyping a custom part or planning a full-scale production run, our team in Union, NJ, is ready to help. We offer rapid quotes, local support, and expert guidance from start to finish.

📞 Call us at (908) 688-0800

📍 Visit our Union facility to tour our equipment and meet our engineers

💬 Request a quote online and tell us about your next project

Let DureX be your trusted fabrication partner—from concept to completion.

Frequently Asked Questions

What is the difference between CNC machining and metal stamping?

CNC machining removes material from a solid block using computer-controlled tools, making it ideal for complex parts and tight tolerances. Metal stamping uses dies and presses to shape thin sheet metal, making it cost-effective for high-volume production of simpler parts.

Which process is better for high-volume manufacturing?

Metal stamping is typically better for high-volume production because it offers lower cost per part once tooling is complete. CNC machining is better for smaller batches, prototyping, or parts that require frequent design changes.

Can DureX help me decide which method to use?

Yes. Our engineering team works closely with you to evaluate your part design, material requirements, and production volume to determine whether CNC machining, stamping, or a hybrid method is the best fit.

What types of materials can you machine or stamp?

We work with a broad range of metals including aluminum, steel, stainless steel, brass, and copper. CNC machining handles thicker and harder materials, while stamping is ideal for thin sheet metal.

Is CNC machining more precise than metal stamping?

Yes. CNC machining offers superior precision and is ideal for parts with complex geometries or tight tolerances, such as components for medical devices or aerospace systems.

Does DureX offer rapid prototyping services?

Absolutely. We provide rapid prototyping using CNC machining and additive manufacturing. This allows you to validate designs before committing to full production or stamping die costs.

Where are your metal fabrication services located?

Our 120,000 sq. ft. facility is located in Union, New Jersey, serving clients across New Jersey, New York, Pennsylvania, and the entire East Coast. We offer local service with nationwide capability.

How do I get a quote for my project?

You can call us at (908) 688-0800 or use our online quote request form. Send us your design files or project specs, and we’ll recommend the best manufacturing solution and turnaround time.