Metal enclosures are the backbone of countless modern products—from electronics and telecommunications hardware to industrial machinery and consumer appliances.

Their role is functional and protective: they safeguard delicate circuitry, provide structural integrity, and ensure safety and performance standards compliance.

For engineers, product designers, and manufacturing decision-makers, choosing the right fabrication process for metal enclosures is more than a cost decision—it affects precision, durability, lead times, and scalability.

\Three widely used methods are CNC machining, stamping, and welding. Each comes with distinct strengths, limitations, and best-fit applications.

This article explores these processes in depth, compares them side by side, and examines how they can be combined to create efficient, high-quality manufacturing workflows.

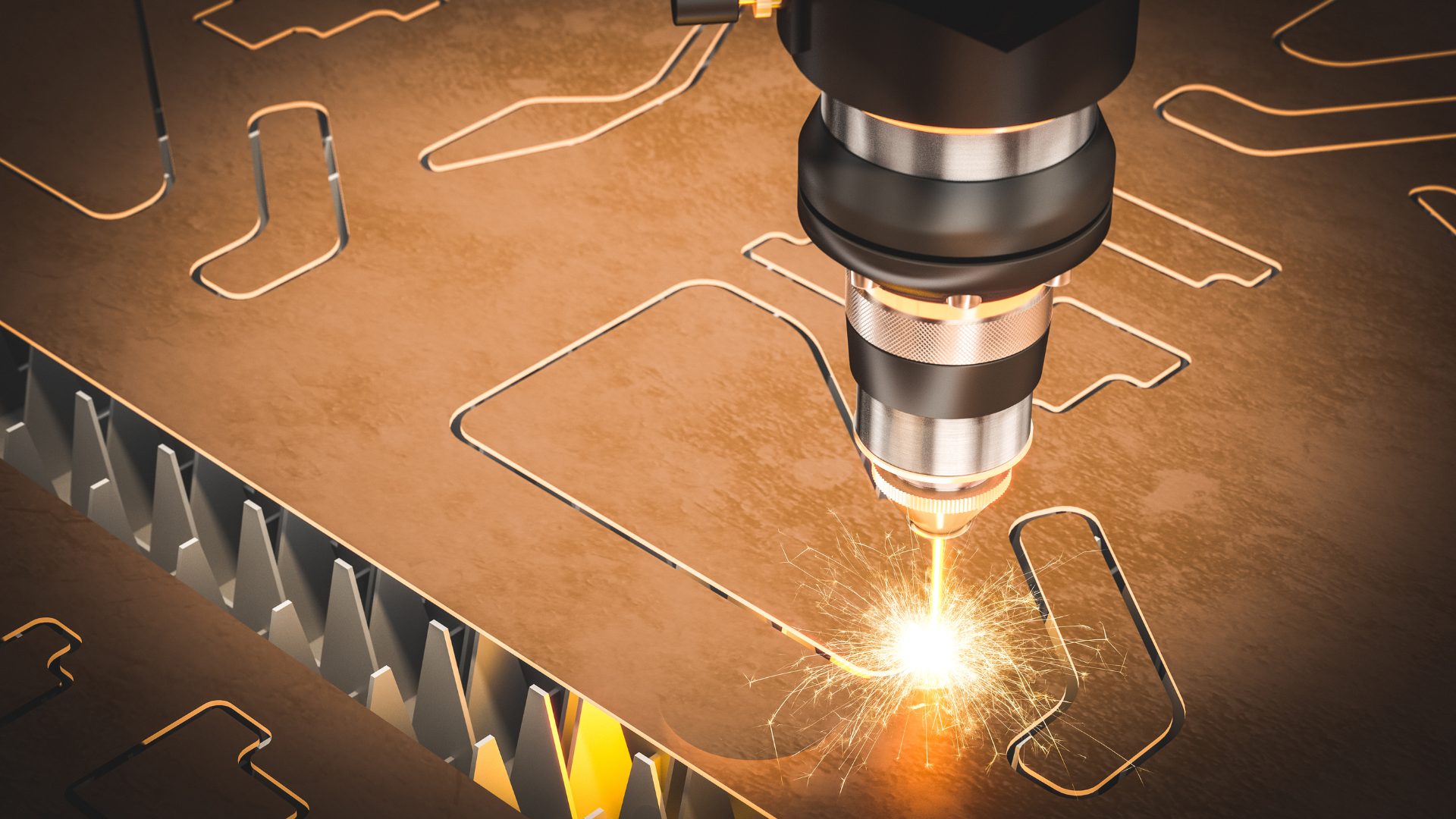

CNC Machining for Metal Enclosures

CNC machining has become a cornerstone in metal enclosure fabrication, offering unmatched precision, repeatability, and design flexibility for industries ranging from electronics to aerospace.

Unlike stamping or soft tooling, which are often optimized for high-volume production, CNC machining allows manufacturers to produce complex geometries, tight tolerances, and customized designs without the expense of dedicated tooling.

This makes it especially valuable for prototypes, low- to mid-volume runs, and applications where quality and accuracy are critical.

As digital manufacturing advances, CNC machining continues to play a vital role in bridging the gap between rapid prototyping and scalable production, giving OEMs the ability to bring enclosure designs to market faster and with greater confidence.

How CNC Machining Works

CNC (Computer Numerical Control) machining uses programmed instructions to guide cutting tools across a block of material, removing stock to achieve the desired geometry. For enclosures, CNC typically involves milling and drilling operations to produce precise panels, cutouts, and tapped holes.

CNC machines can work with a wide range of materials—aluminum, stainless steel, mild steel, and high-performance alloys—while maintaining tight tolerances down to ±0.001 in. (0.025 mm).

Benefits of CNC in Enclosure Fabrication

- High Precision and Accuracy – Ideal for enclosures requiring tight tolerances for electronic components, thermal management, or sealing features.

- Flexibility in Design – Complex geometries, internal channels, or intricate cutouts can be produced without costly tooling.

- Low Volume, High Variety – CNC is cost-effective for prototypes, pilot runs, or custom enclosures with frequent design changes.

- Material Versatility – Works with metals of varying hardness, thickness, and coatings.

Drawbacks

- Cost at Scale – Per-part costs remain relatively high because material is removed rather than formed, and cycle times are longer.

- Throughput Limitations – Compared to stamping, CNC is slower for mass production.

- Waste Generation – Subtractive machining produces scrap material, which requires recycling or disposal.

Best Use Cases

- Prototyping enclosures for new electronic devices.

- Low-volume industrial control panels with unique cutouts.

- Custom enclosures requiring precision fit for aerospace or medical devices.

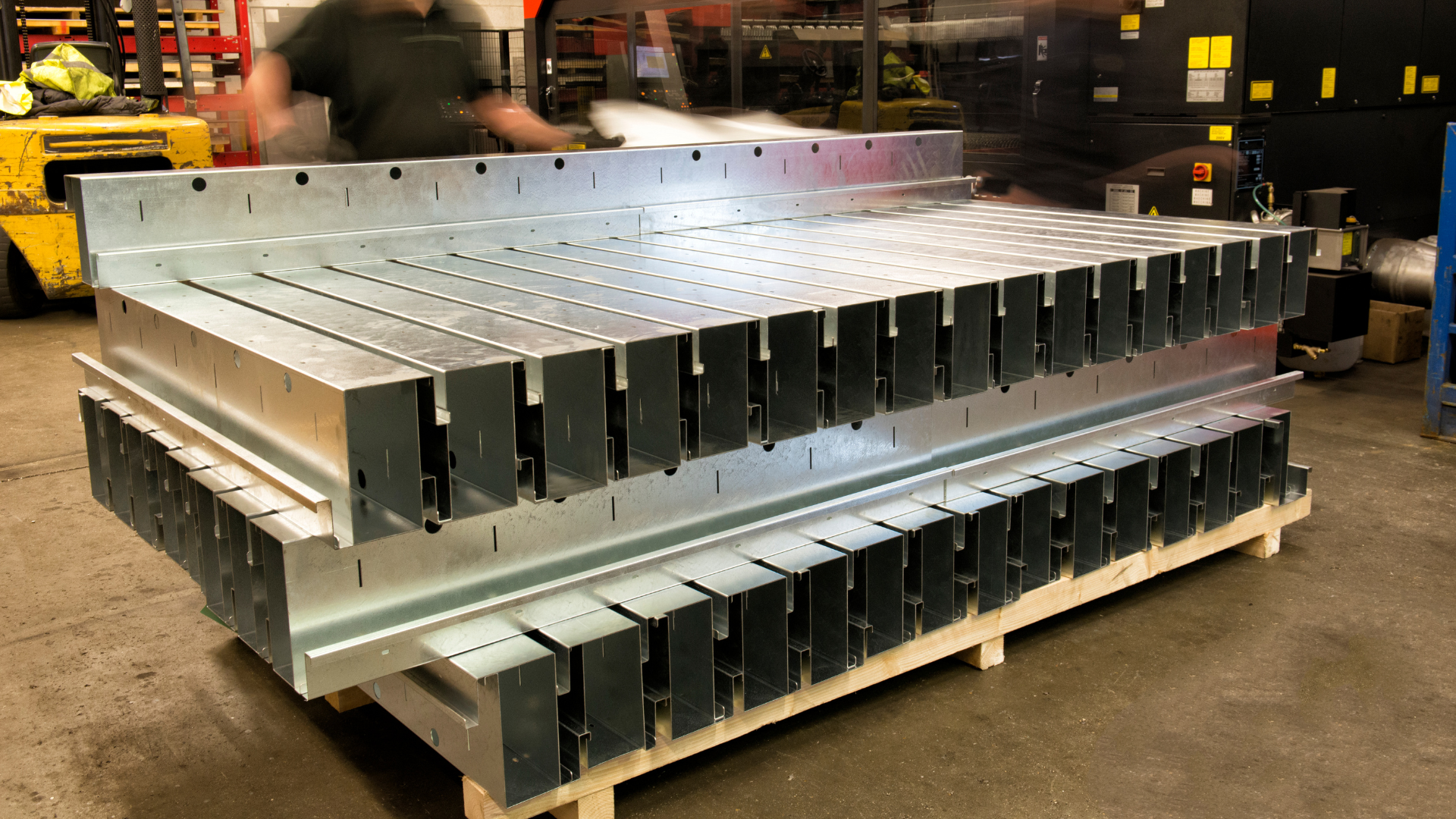

How Metal Stamping Works

Stamping uses a press and a set of hardened dies to cut, punch, and form sheet metal into enclosure shapes. Processes include blanking, piercing, bending, and deep drawing. Stamping is highly automated and capable of producing thousands of identical parts per hour.

Benefits of Stamping

- Scalability and Speed – Once tooling is made, stamping is unmatched for producing large quantities of consistent enclosures.

- Cost Efficiency at Volume – The high initial tooling cost is offset by low per-unit cost at medium to large production runs.

- Material Utilization – Sheet nesting and coil feed systems minimize waste.

- Repeatability – Ideal for industries where interchangeable parts are critical.

Drawbacks

- Tooling Investment – Die design and fabrication can cost tens of thousands of dollars.

- Design Limitations – Stamping excels at flat and bent geometries but is less suitable for deep, intricate, or highly customized designs.

- Lead Time for Tooling – Initial setup may take weeks before production can start.

Best Use Cases

- High-volume production of consumer electronics housings.

- Automotive control box enclosures.

- Standardized industrial enclosures with limited variation.

Role of Welding in Enclosures

While CNC and stamping create enclosure panels and parts, welding is often required to join components into a rigid, permanent structure. Welding methods vary depending on material, thickness, and production scale.

Benefits of Welding

- Strength and Permanence – Welded joints are strong and secure, ideal for enclosures exposed to vibration, load, or environmental stress.

- Design Flexibility – Enables joining of different shapes and reinforcing structural features.

- Range of Techniques – MIG (GMAW), TIG (GTAW), spot welding, and advanced processes like laser welding provide options tailored to enclosure needs.

- Automation Potential – Robotic welding delivers repeatability, speed, and reduced labor costs.

Drawbacks

- Labor Intensity – Manual welding requires skill and adds labor costs.

- Heat Distortion – Thermal stresses can cause warping, especially in thin-gauge sheet metal.

- Post-Processing – Grinding, finishing, or coating may be needed to achieve the desired surface quality.

Modern Welding Trends

- Laser Welding – Provides minimal heat input, narrow weld seams, and reduced distortion, ideal for precision electronics enclosures.

- Robotic Welding – Increases speed and consistency for repetitive enclosure assembly tasks.

- Hybrid Welding – Combines laser and arc welding to optimize strength and efficiency.

Best Use Cases

- Enclosures for industrial machinery requiring heavy-duty frames.

- Weatherproof outdoor housings needing sealed seams.

- Custom low-volume enclosures assembled from CNC-cut panels.

Pros and Cons Comparison Table

| Process | Strengths | Weaknesses | Best For |

| CNC Machining | High precision, flexibility, no tooling required | Higher cost per part, slower at scale, waste material | Prototypes, low-volume runs, complex geometries |

| Stamping | Fast, cost-effective at volume, and excellent repeatability | High tooling cost, limited design flexibility, and long setup times | High-volume production, standardized parts |

| Welding | Strong, permanent joints, flexible joining options | Labor-intensive, risk of distortion, may require finishing | Structural enclosures, sealed housings, and assembly |

When to Combine Processes

In practice, manufacturers rarely rely on a single method. Instead, they combine CNC, stamping, and welding to balance flexibility, cost, and performance.

- CNC for Prototyping, Stamping for Production

A design may start with CNC machining to validate dimensions and performance. Once finalized, stamping dies are built for mass production. - Laser-Cut Panels + Forming + Welding

Panels are laser-cut for accuracy, bent on press brakes, then welded together to create the final enclosure. - CNC Secondary Operations on Stamped Parts

Stamped enclosures may require tapped holes, countersinks, or fine machining—tasks suited to CNC as a finishing step. - Robotic Welding in Stamping Lines

Automated weld cells integrate directly with stamping lines, ensuring enclosure assembly at scale.

Industry Trends in Enclosure Fabrication

As industries from electronics to HVAC and medical equipment push for faster, more cost-effective, and scalable production, enclosure fabrication is evolving through a mix of traditional and advanced methods.

Trends show that OEMs are increasingly balancing short-run flexibility with long-term economies of scale by leveraging soft tooling, CNC machining, stamping, and hybrid approaches.

At the same time, the rise of one-stop manufacturers offering fabrication, stamping, machining, and finishing under a single roof is reshaping supply chains, helping companies reduce costs, consolidate vendors, and scale smoothly as demand grows.

This shift highlights a broader industry movement toward efficiency, adaptability, and strategic partnerships in enclosure fabrication.

Automation and Robotics

Smart factories increasingly integrate CNC machines, stamping presses, and robotic welding systems into a unified digital workflow. This enables lights-out manufacturing, predictive maintenance, and real-time quality monitoring.

Sustainability

Manufacturers are prioritizing material efficiency and recycling. CNC processes now leverage optimized toolpaths and scrap reclamation, while stamping lines use coil feed systems to reduce waste. Welding technologies like laser joining minimize energy input.

Smart Enclosures

As electronics become more sophisticated, enclosures must accommodate thermal management, EMI shielding, and modularity. This trend pushes fabrication toward processes capable of high precision and customization.

Conclusion

No single fabrication method is universally “best.” The optimal choice depends on production scale, design complexity, material requirements, and budget constraints:

- Choose CNC machining when precision and flexibility outweigh cost.

- Choose stamping for high-volume, standardized enclosures where speed and cost efficiency are paramount.

- Choose welding when structural integrity or sealed joints are required.

Most importantly, these methods are not mutually exclusive. The most effective fabrication strategies leverage them in combination, aligning with evolving industry trends toward automation, sustainability, and intelligent design.