In sheet metal manufacturing, the decision between soft tooling vs hard tooling affects cost, flexibility, and production outcomes.

Each approach has specific advantages depending on design maturity, production volume, and required tolerances.

Choosing the right one early in a project’s lifecycle can influence not just manufacturing efficiency but also how quickly a product can move from concept to market.

Tooling determines how raw metal is shaped into usable components. It defines the setup cost, cycle time, repeatability, and ability to scale.

Engineers and procurement managers face the same question across industries: whether to begin with flexible, digitally controlled soft tooling or invest in long-lasting, high-efficiency hard tooling.

This article outlines how each method works, the economic and technical trade-offs involved, and when it makes sense to transition from one to the other.

What Is Soft Tooling?

Soft tooling refers to manufacturing tools or digital setups designed for short production runs, prototypes, or designs still in development. In sheet metal fabrication, this typically includes CNC laser cutting, turret punching, and press brake forming.

These processes create precise parts without the need for permanent dies, allowing quick adjustments when design revisions occur.

Additional context on how these methods are used in practice is available in DureX’s page on custom sheet metal fabrication services, which outlines how flexible fabrication supports both prototype and production environments.

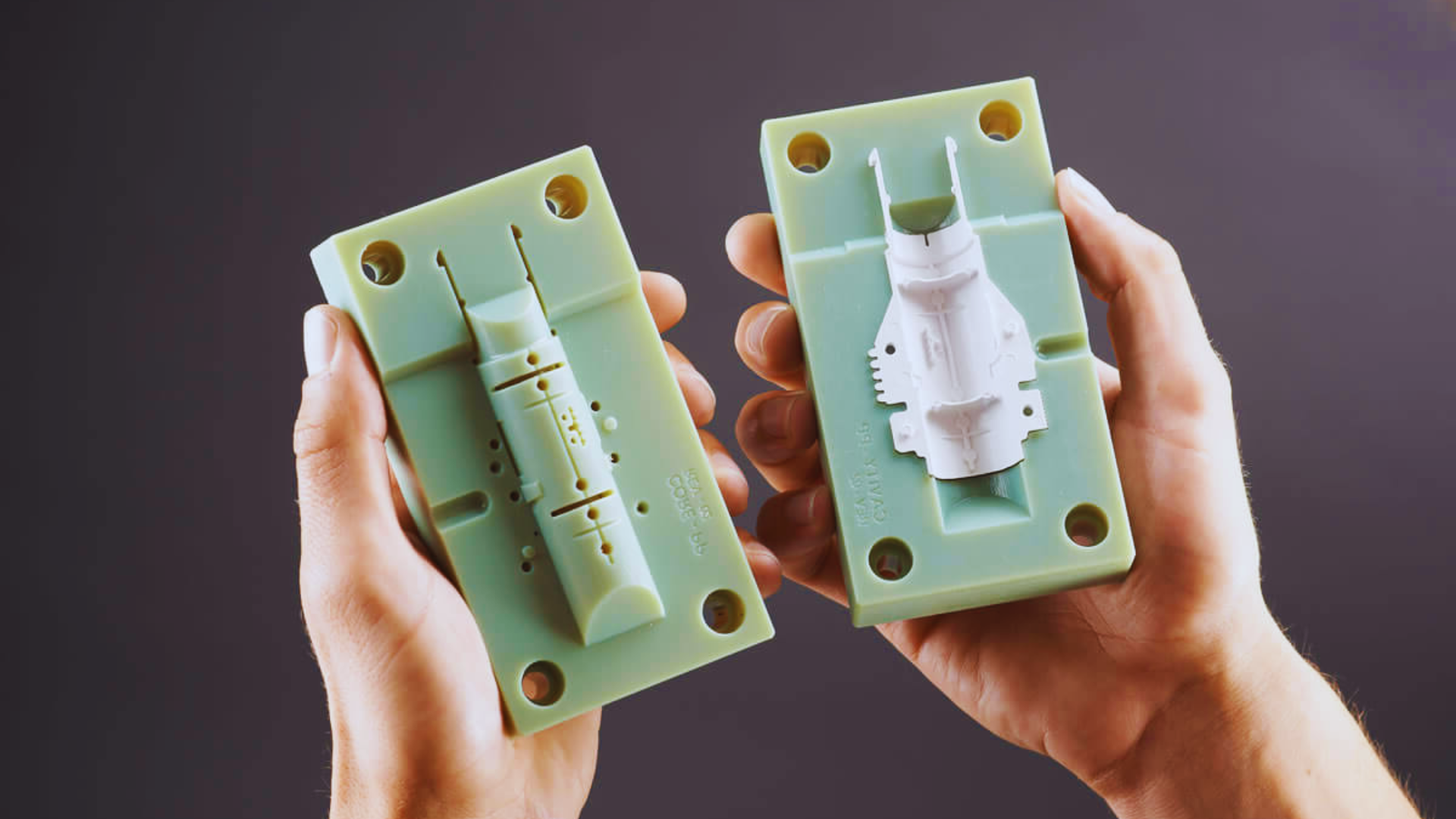

Unlike hard tooling, which uses hardened steel dies, soft tooling is often made from aluminum or composite inserts.

The initial cost is therefore much lower, usually between $75 and $3,000, according to Consumables Online. While these tools wear faster, their affordability and speed of implementation make them well-suited for prototype and pilot production.

Many manufacturers extend the value of soft tooling through the reuse of existing components. As Consumables Online notes, DureX Inc. has developed an extensive library of punches, dies, and forming tools accumulated over decades of production.

When part geometry matches existing profiles, these tools can be used again, avoiding the need for new fabrication and reducing lead time.

Because soft tooling relies on CNC programs rather than fixed dies, it aligns naturally with flexible manufacturing systems. This adaptability allows multiple product variations to be produced using the same equipment.

It is particularly valuable when volumes are low or part designs are still evolving, since engineers can validate function and fit without committing to high tooling expenses.

The techniques used in soft tooling are the foundation of modern fabrication workflows. They enable rapid transitions from digital design to physical parts, often within hours.

This process supports bridge manufacturing, where early units are built using temporary setups before permanent dies are complete, and helps maintain continuity between design, testing, and production.

For a broader technical perspective, Manufacturing Tomorrow discusses how soft tooling delivers speed and flexibility in early-stage production across varied manufacturing sectors.

What Is Hard Tooling?

Hard tooling represents the opposite end of the manufacturing spectrum. It involves permanent, high-precision dies typically made of hardened tool steel and designed for long-term, high-volume production.

These dies are custom-engineered to a specific part and can produce thousands or even millions of consistent components once commissioned.

The cost of hard tooling varies widely depending on size, complexity, and the number of integrated operations.

Industry reports estimate prices ranging from $5,000 to over $300,000. Unlike soft tools, which are adjusted digitally, hard tooling must be physically built, inspected, and tested before use.

The lead time can extend several weeks, but once in service, these tools operate quickly and with minimal variation.

The efficiency comes from how much work is performed in a single press stroke. Hard tooling is used in stamping presses or forming dies that can blank, pierce, bend, and coin simultaneously.

Progressive dies take this a step further, combining multiple stages into a continuous strip process that outputs a finished part with each press cycle. The result is fast throughput, low per-unit cost, and repeatable quality.

Because the geometry of a hard tool is fixed, changes after fabrication are difficult and expensive.

For that reason, most manufacturers delay investment until part design is finalized and projected volume justifies the cost. Once in production, however, these tools can run for years with routine maintenance.

Hard tooling involves permanent dies designed for precision and longevity. Once fabricated, these tools are capable of producing thousands or even millions of identical components with minimal variation.

Because they are built from hardened steel and designed to hold tight tolerances, their fabrication and maintenance require a higher level of engineering control. ScienceDirect’s overview on hard tooling which outlines the characteristics and performance factors associated with tooling for high-volume manufacturing.

Key Differences Between Soft and Hard Tooling

The differences between soft and hard tooling go beyond cost. They reflect distinct manufacturing philosophies, one optimized for flexibility, the other for efficiency. Understanding these distinctions helps determine when the transition between them should occur.

Soft tooling favors low upfront cost and adaptability. Machine time is longer because each part is cut and formed individually, but no dedicated die investment is required.

Hard tooling reverses that equation: the upfront expense is high, yet cycle times are measured in seconds once production begins.

Durability is another factor. Soft tools wear faster and may require replacement after limited use; hard tools can last for hundreds of thousands of parts.

| Aspect | Soft Tooling | Hard Tooling |

| Initial Cost | Low | High |

| Lead Time | Short | Long |

| Cycle Time | Slower | Fast |

| Flexibility | Easily adjustable | Fixed geometry |

| Durability | Limited | Long lifespan |

| Best Use | Prototypes, short runs | High-volume production |

The Industrial Machinery Digest article on production scaling describes this relationship as an ROI threshold. In one documented example, a sheet metal chassis and cover initially fabricated at $22 per unit were later produced through stamping for $14 per unit.

Although the hard tooling cost was around $80,000, the return on investment was achieved in less than four months. Once that threshold is crossed, per-unit savings compound rapidly.

Hard tooling also improves process capability. Tolerances become more consistent, and the risk of operator variation is reduced.

For OEMs supplying regulated industries, such as electronics, medical, or transportation, this repeatability can be essential. For broader fabrication practices integrating both tool types, see DureX’s sheet metal fabrication in NJ.

When to Choose Soft Tooling

Soft tooling is selected when projects demand design flexibility, low capital risk, and quick turnaround. It is common in early-stage development and for products with unpredictable demand.

The approach suits engineering teams refining form and fit or companies producing limited runs for testing or specialty markets.

One advantage is the ability to make changes without significant rework. A revised CAD file can be uploaded to a CNC system within hours, allowing immediate production of updated parts.

This agility supports continuous improvement and rapid iteration, which are difficult to achieve with permanent dies.

Soft tooling is also appropriate for bridge manufacturing, a temporary stage that provides parts while hard tooling is being built.

This keeps assembly lines running during development, ensuring that delays in die construction do not interrupt deliveries.

In industries with frequent design revisions, such as telecommunications or medical devices, soft tooling may even remain the long-term solution.

Another consideration is forecast uncertainty. When market acceptance of a new product is unclear, soft tooling allows companies to limit upfront spending until demand stabilizes.

According to Consumables Online, some suppliers maintain inventories of reusable soft tools that can be borrowed or repurposed for new orders, further reducing cost. This strategy lets OEMs validate market potential without committing to expensive dies prematurely.

The flexibility of soft tooling aligns with lean manufacturing principles. It supports small-batch production, on-demand ordering, and customization.

However, once production exceeds several thousand units or requires highly consistent dimensions, the economics begin to favor hard tooling.

When to Choose Hard Tooling

Hard tooling becomes the logical choice when production volumes are high, tolerances are tight, and long-term repeatability is critical. At this stage, investing in dedicated dies offers the lowest per-unit cost and the greatest process stability.

Before switching, manufacturers typically perform a cost analysis comparing tooling investment to potential savings per part.

Using the earlier DureX example, if a part costs $8 less to produce under hard tooling and 3,000 parts are ordered monthly, the savings reach $24,000 per month, enough to recover an $80,000 tooling cost in roughly 3.5 months. Beyond that point, all subsequent production benefits directly from lower unit costs.

Hard tooling is also essential for geometries that require multiple simultaneous operations or very close tolerances. Progressive and staged dies can blank, form, and pierce features in one press cycle, greatly reducing handling.

As production volumes climb, this automation minimizes labor input and ensures uniformity between batches.

However, the transition should only occur once the part design is stable. Unlike CNC programs that can be edited digitally, changes to steel dies require machining and heat treatment, which add cost and delay.

A hybrid approach can help bridge this gap: flat blanks can be produced through laser cutting or turret punching (soft processes) and then formed in a dedicated hard die.

The Consumables Online article described this method, reducing production time for a light-fixture component from two minutes to about thirty seconds per part.

Hard tooling also simplifies downstream logistics. Identical parts stack, fit, and assemble more predictably, improving flow across welding, coating, or final assembly. Once production enters a sustained phase, this consistency outweighs the initial investment.

For projects where precision machining complements high-volume forming, see DureX’s precision CNC machining in NJ.

Evaluating Cost, Flexibility, and ROI

When comparing soft and hard tooling, cost per part alone does not tell the full story. Engineers often evaluate three variables together: volume, design stability, and time horizon. Each influences when the break-even point occurs.

For instance, a small program requiring 2,000 parts might rely on soft tooling costing $2,000 and a $25 per-part price. Total cost would be $52,000.

A large program with a hard tool costing $80,000 but a $14 per-part cost reaches $220,000 after 10,000 units, but the savings grow sharply beyond that threshold. The longer the production run, the faster the initial expense is recovered.

Forecast accuracy, therefore, plays a major role. If demand is uncertain or the product is expected to change, soft tooling remains the safer option. If orders are steady and the geometry is final, hard tooling becomes the more economical choice.

Many manufacturers perform this analysis at multiple stages of a program to identify the optimal transition point.

Operational Considerations

Selecting between soft and hard tooling involves more than economics. Each method influences how a production program operates day to day, from scheduling and maintenance to inspection practices and material selection.

Even when the return-on-investment point seems clear, operational realities often determine how effectively that tooling performs in practice.

Before committing to one approach, engineers and procurement teams typically evaluate production timelines, equipment availability, and the life expectancy of the tool itself.

These factors ensure the selected tooling not only meets design intent but also integrates smoothly into the manufacturing flow.

The following considerations highlight where differences between soft and hard tooling become most apparent in real-world production.

Lead Time and Scheduling

Lead time for soft tooling is generally measured in days, while hard tooling can require several weeks to design, machine, and qualify.

Companies facing compressed launch schedules often begin fabrication using soft tooling and later transition once the permanent dies are complete. This staged approach maintains supply continuity during development and testing phases.

Maintenance and Longevity

Both soft and hard tools require attention to stay accurate, but the frequency and complexity of maintenance differ.

Hard tools need periodic lubrication, alignment checks, and sharpening to ensure clean edges and consistent forming.

While this adds some cost, properly maintained dies can last for years. Soft tools, built from lighter materials, wear faster but are inexpensive to replace and easier to modify when geometry changes. The choice depends on production life and expected tolerance stability.

Quality Control and Tolerances

Dimensional consistency improves significantly under hard tooling. Once a die is proven, each cycle produces nearly identical results with minimal operator variation.

Soft tooling, though capable of fine precision, depends more on setup accuracy and machine calibration, leading to slightly greater variability.

For assemblies that require a perfect fit, such as frames, enclosures, or multi-part housings, hard tooling provides a measurable advantage.

Material and Design Compatibility

Different metals react uniquely to forming pressure and temperature. Thin-gauge steel or aluminum is well-suited for stamping, while thicker or high-strength materials may perform better under CNC fabrication methods.

Early coordination between design and manufacturing teams ensures the process selected aligns with material behavior, minimizing defects and maximizing tool life. Matching tooling type to material properties is an essential part of achieving repeatable quality.

FAQs

Is soft tooling cheaper than hard tooling?

Soft tooling has a lower initial cost because it uses existing equipment and general-purpose tools instead of dedicated dies. However, while setup is inexpensive, the per-part cost tends to be higher due to longer cycle times. Hard tooling requires significant upfront expense but achieves the lowest cost per part in sustained production runs.

Which lasts longer: soft or hard tooling?

Hard tooling offers far greater durability. Dies made from hardened steel can produce hundreds of thousands of parts before major refurbishment is needed. Soft tools, typically made from aluminum or mild steel inserts, are suitable for limited runs or prototyping but wear more quickly under repeated use.

When should a company invest in hard tooling?

A company should consider hard tooling once product design is finalized and production forecasts indicate steady, high-volume demand. This transition generally occurs when order quantities exceed several thousand units annually, allowing the tooling cost to be recovered quickly through reduced part pricing and faster throughput.

Can a project combine both soft and hard tooling?

Yes. Hybrid strategies are common in modern fabrication. For example, a part may be laser-cut or turret-punched (soft tooling) and then formed in a dedicated die (hard tooling). This approach reduces time in early runs while introducing efficiency gains as volume increases, providing a balanced path between flexibility and cost control.

How do material and part complexity affect tooling choice?

Material type, thickness, and geometry heavily influence which tooling method is most effective. Thin or ductile metals form well in stamping dies, while thicker or hardened alloys may require CNC fabrication. Complex shapes with multiple bends or cutouts sometimes benefit from staged or progressive tooling to maintain accuracy without excessive handling.

Conclusion

Soft and hard tooling represent two points on the same manufacturing continuum. The first emphasizes flexibility and speed; the second delivers efficiency and consistency. Most production programs use both at different stages. Early development relies on soft tooling to refine designs quickly and cost-effectively. Once a product reaches maturity and demand stabilizes, transitioning to hard tooling supports lower unit costs and predictable quality.

The decision should be guided by data, expected volume, lifecycle duration, tolerance requirements, and the cost of design changes. A well-timed shift from soft to hard tooling can improve margins, reduce waste, and align production capacity with long-term demand. Viewing tooling as a strategic variable rather than a fixed expense allows manufacturers to balance adaptability with efficiency throughout the product’s lifecycle.

Soft tooling supports rapid prototyping and low-volume fabrication through CNC-controlled flexibility, while hard tooling provides durable, high-precision dies for mass production. The transition point depends on ROI, design stability, and volume forecasts.