Selecting the right metal-forming process can make or break a manufacturing program. For OEM engineers and procurement teams across New Jersey and the U.S., the choice between custom sheet metal fabrication vs stamping defines how quickly parts reach market, how much they cost, and how consistently they perform. Both methods convert flat metal into precision components, but they do so in dramatically different ways.

Fabrication emphasizes adaptability and precision across varied geometries, while stamping focuses on speed and repeatability at scale. Understanding these distinctions helps manufacturers align process capabilities with project goals, ensuring that every part, whether a prototype or a mass-produced chassis, is delivered efficiently and within tolerance.

What Is Custom Sheet Metal Fabrication?

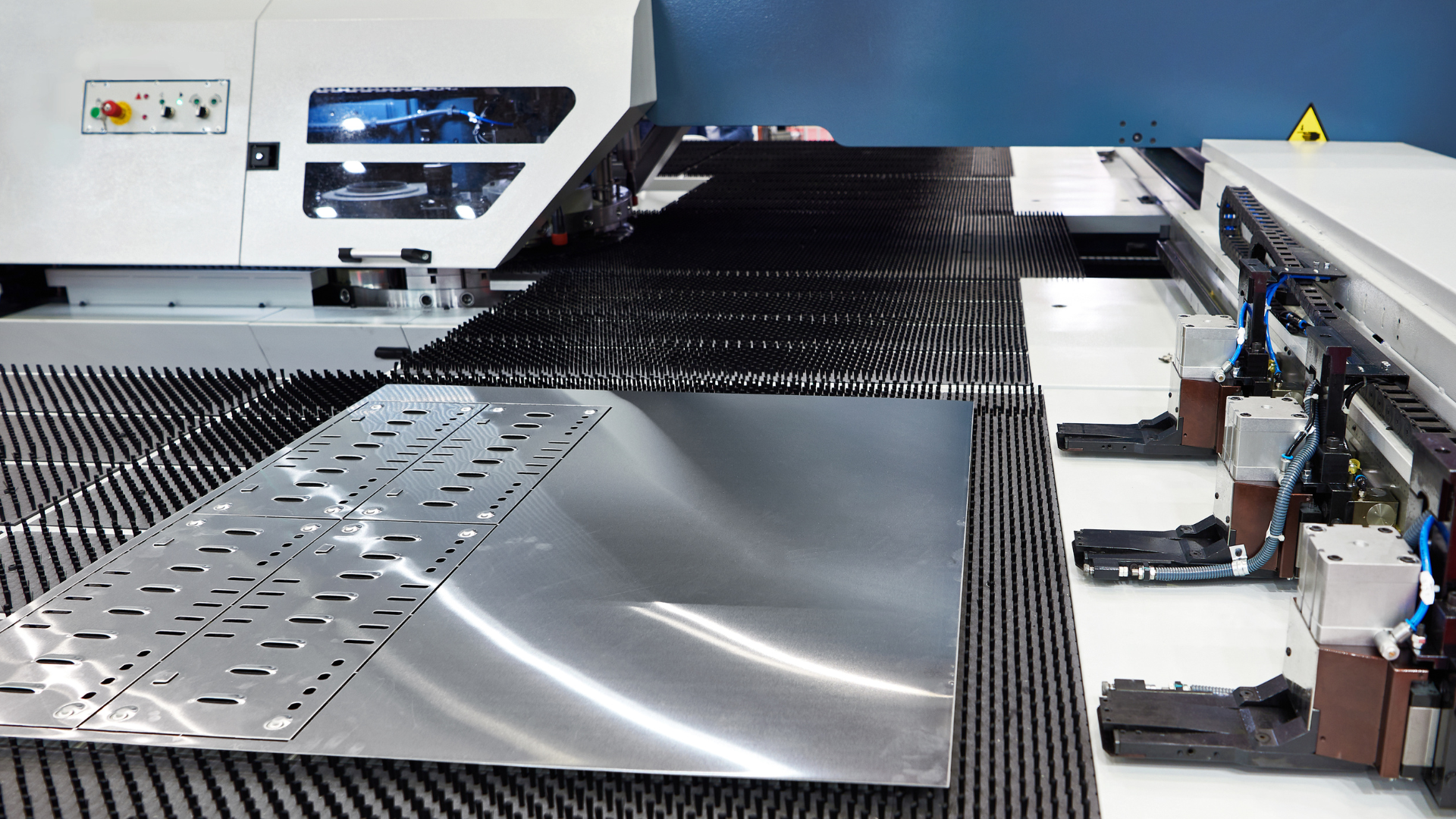

Custom sheet metal fabrication is the foundation of modern component engineering. It turns raw sheets of aluminum, stainless steel, or mild steel into durable parts through programmable operations such as cutting, bending, welding, and finishing.

Instead of relying on expensive dies, fabrication uses digital machinery and modular setups to produce complex or low-volume parts quickly.

This flexibility makes fabrication indispensable to industries that demand precision and iteration, electronics, HVAC, medical devices, transportation, and defense.

In New Jersey, where DureX Inc. operates one of the region’s most advanced manufacturing facilities, fabrication enables companies to move seamlessly from concept to production without committing to tooling costs or minimum orders.

Once a design is approved, laser cutters and turret presses define the geometry, press brakes form the structure, and skilled welders or robotic systems join sub-assemblies before surface finishing.

This workflow balances customization with consistency, illustrating how custom sheet metal fabrication services integrate multiple processes to achieve precise, repeatable results across both prototype and production environments.

What Is Stamping?

Metal stamping represents the other end of the production spectrum, built for high throughput and identical results. The process uses precision-machined dies fitted into mechanical or hydraulic presses that cut, punch, or form metal sheets at remarkable speed.

Each press stroke can yield one or more finished components, allowing thousands of parts to be produced every shift with minimal variation.

Because stamping requires dedicated tooling, it excels when part design is finalized and production volume justifies the investment. Typical stamped parts include brackets, panels, enclosures, and structural supports.

According to the Approved Sheet Metal (ASM) overview on the differences between fabrication and stamping, the efficiency of this process depends largely on tooling design, material thickness, and the press tonnage applied during production.

At DureX Inc., stamping operations draw on presses up to 400 tons, delivering consistent tolerances across large batches while reducing per-piece cost once the tooling is paid for.

President Bob Denholtz summarizes the trade-off succinctly: “With a sheet-metal part that costs $10, stamping may bring it down to $6, but only if you produce enough volume to offset a $30,000 to $40,000 tooling cost.”

Key Differences: Cost, Speed, Flexibility, and Precision

Comparing sheet metal fabrication vs stamping begins with economics. Fabrication avoids the heavy upfront expense of dies, relying instead on digital cutting and forming equipment.

This makes it ideal for short runs or products in development. Stamping carries substantial tooling costs but rapidly reduces the per-unit price at scale, a dynamic supported by Newayprecision Insights on cost efficiency in metal manufacturing.

Speed follows a similar pattern. Fabrication requires multiple machine setups and manual handling, but can launch immediately after CAD approval. Stamping, once tooled, produces hundreds of parts in seconds.

Flexibility, however, favors fabrication: engineers can alter geometry or material without re-cutting dies, something impossible in a stamping line.

Precision depends on the design. Fabrication achieves tight tolerances for intricate or welded assemblies; stamping ensures uniformity across large batches.

In short, fabrication offers agility and customization, stamping delivers scale and repeatability. The most efficient manufacturers know when to pivot between the two.

When to Choose Fabrication

Fabrication is the logical starting point for any project in which requirements may evolve or demand is uncertain. It supports prototyping, small-to-medium production, and complex assemblies that benefit from iterative design. By removing the need for custom dies, fabrication minimizes startup time and financial risk.

OEMs across New Jersey often begin with fabrication to validate form, fit, and function before committing to stamping. DureX Inc. illustrates this approach in a case highlighted by Industrial Machinery Digest: a power-supply chassis initially produced at 500 units per month was fabricated without tooling costs.

When volume later rose to 5,000 units, the company transitioned the same design to hard tooling, dropping the price from $22 to $14 per unit.

The tooling ROI arrived in under four months. Fabrication is also preferable when aesthetics, weld quality, or multi-material integration are as critical as throughput.

In regions like New Jersey, sheet metal fabrication plays a key role in supporting agile, high-mix production by allowing manufacturers to adapt processes and finishes to meet diverse design and performance requirements.

When to Choose Stamping

Once volumes stabilize and repeatability outweighs flexibility, stamping becomes the smarter long-term investment. It shines in high-volume production where tooling amortization quickly offsets its cost.

OEMs producing tens of thousands of identical components can reduce labor time dramatically and ensure dimensional consistency across every batch.

A feature in Consumables Online documented how a client manufacturing electrical enclosures reduced per-part cost from $22 to $15 after switching from soft-tool fabrication to hard-tool stamping.

Although the tooling required roughly $85,000 up front, the ROI was achieved in just four months, saving tens of thousands annually. For very large runs, progressive dies can complete cutting, forming, and piercing in a single stroke, yielding a finished part every few seconds.

Stamping, therefore, suits mature products with stable geometry, predictable demand, and tight delivery schedules. The process is less about versatility and more about economy, ideal for automotive, appliance, and industrial OEMs operating at scale.

Hybrid and Transitional Approaches

Between prototype and full production lies a valuable middle ground: hybrid tooling. By combining fabrication and stamping techniques, manufacturers gain both flexibility and efficiency.

A flat blank may be laser-cut and partially formed in a turret press before a hard tool shapes it into a final box. This staged process trims cycle time without full die investment.

DureX Inc. routinely applies such hybrids for HVAC and electronic enclosures, allowing customers to ramp volumes gradually.

These transitional methods ensure that no tooling dollar is wasted, fabrication handles the early phase, stamping takes over once demand justifies it, and both can coexist when assemblies include parts of varying complexity.

The strategy underscores DureX’s integrated model: a single facility offering laser cutting, turret punching, press braking, welding, and high-tonnage stamping, all supported by in-house engineers who calculate each project’s ROI threshold before recommending the shift.

Volume and Economics

Production volume remains the decisive factor. Studies across the industry show the economic crossover between fabrication and stamping generally occurs around 10,000 to 20,000 units per year. Below that, fabrication’s flexibility outweighs its per-part cost; above it, stamping’s speed dominates.

For example, if a fabricated part costs $10 with no tooling, while stamping cuts it to $6 but requires a $40,000 die, the breakeven arrives at roughly 10,000 parts.

Every unit beyond that saves $4. For high-growth OEMs, the best path is often to fabricate prototypes and early runs, monitor demand, then invest in stamping once orders consistently exceed that threshold.

Because DureX Inc. provides both capabilities under one roof, New Jersey manufacturers can make that transition seamlessly, avoiding supply-chain disruptions or requalification delays that occur when switching vendors.

Other Decision Factors

While volume is primary, several secondary elements refine the choice: material, geometry, and lead time. Fabrication handles thicker gauges and a broader range of alloys, including stainless, aluminum, and copper. Stamping is optimized for thinner stock that withstands rapid forming without cracking.

Complexity also matters. Multi-component weldments, assemblies with threaded inserts, or designs requiring cosmetic finishes usually favor fabrication. Simple flat or shallow-draw parts favor stamping.

Lead-time expectations further influence selection: fabrication delivers prototypes within days, while stamping requires weeks for tool design and validation, but then runs continuously at high output.

For many OEMs, the deciding factor is partnership. A vertically integrated manufacturer capable of fabrication, stamping, and CNC machining can adapt as needs change.

DureX Inc.’s cross-disciplinary team frequently evaluates all three options to recommend the most cost-effective combination for each stage of a product’s life cycle.

Frequently Asked Questions

Is stamping cheaper than fabrication?

Stamping becomes cheaper only at higher production volumes. Once the cost of tooling is recovered, the per-part price can drop substantially. For smaller runs or projects with evolving designs, fabrication is often the more economical choice because it avoids expensive dies.

Which process offers better precision?

Both fabrication and stamping can achieve high precision. Fabrication excels with intricate or multi-part assemblies where welding, finishing, or machining are required. Stamping ensures uniformity across thousands of identical parts, ideal for consistent, high-speed output.

Which is faster for large projects?

Stamping is significantly faster once tooling is in place, often producing finished parts in seconds. Fabrication, however, offers a quicker startup for prototypes and small-batch runs since it doesn’t require die manufacturing.

When should I transition from fabrication to stamping?

Most manufacturers switch to stamping when volumes exceed 10,000–20,000 parts per year. At this point, the cost savings from tooling investment outweigh the higher per-unit cost of fabrication. Hybrid approaches can help bridge this transition efficiently.

Can fabrication and stamping be combined?

Yes. Many OEMs use a hybrid model, fabricating complex components while stamping simpler ones from the same assembly. This approach balances cost, precision, and speed, ensuring scalability without overinvesting in tooling too early.

Decision Framework

Selecting between fabrication and stamping is less about choosing one forever and more about timing the transition correctly. Most OEMs benefit from a progressive workflow: fabricate during R&D, use hybrid tooling during pilot builds, and adopt stamping for full-scale production.

| Stage | Ideal Method | Primary Goal | Key Benefit |

| Prototype / Design Validation | Fabrication | Flexibility | Rapid iteration, no tooling cost |

| Pre-Production / Pilot | Hybrid | Balance | Moderate cost + faster throughput |

| Full Production | Stamping | Efficiency | Lowest cost per unit |

Partnering with an experienced supplier helps ensure each phase aligns with project volume, geometry, and ROI targets. Expertise in CNC machining services in NJ can further complement fabrication and stamping by tightening tolerances on critical features or incorporating machined inserts, allowing for seamless integration between formed and precision-machined components.

Conclusion

For engineers balancing cost, precision, and scalability, the debate over custom sheet metal fabrication vs stamping is really about aligning process capability with production intent. Fabrication provides design freedom and low-risk entry for prototypes and limited runs. Stamping delivers volume efficiency and uniformity once the market demand is proven. Hybrid and staged approaches link the two, letting manufacturers scale without interruption.

Across New Jersey’s industrial base, DureX Inc. embodies this continuum—offering fabrication, stamping, and machining under one roof since 1946. By guiding OEMs through each stage of growth, DureX ensures that every project, from prototype to progressive die, achieves the optimal balance of cost, speed, and precision.

In the end, the smartest manufacturers don’t pick sides; they build adaptable strategies that evolve with their products, leveraging both fabrication and stamping to stay competitive in an industry that never stops moving.