In the world of advanced manufacturing, standards are the invisible backbone that holds every process, material, and measurement together. Without them, even the most sophisticated production lines can yield inconsistent results.

For OEMs, where every component has to meet exacting design, safety, and regulatory requirements, those standards aren’t optional; they’re a non-negotiable foundation of trust.

Whether you’re sourcing precision brackets for aerospace applications, medical device housings, or defense electronics structural enclosures, quality is only as strong as the processes that produce it.

That’s where ISO9001 in metal fabrication comes in. It provides a global framework for ensuring that every fabricated or machined part meets consistent quality, traceability, and performance benchmarks, regardless of where it’s made or who makes it.

In today’s connected supply chains, OEMs must rely on partners who have the equipment and expertise and the discipline to follow repeatable, auditable procedures.

ISO9001 certification verifies that discipline. It shows that a fabricator’s commitment to quality isn’t just written on a brochure; it’s embedded in every job traveler, inspection log, and operator checklist that leaves the shop floor.

What Is ISO9001?

ISO9001 is the international benchmark for quality management systems (QMS), maintained by the International Organization for Standardization.

It defines how companies document, monitor, and improve their processes to consistently meet customer and regulatory requirements.

In essence, it ensures that manufacturers don’t just check for quality at the end; they build quality into every step of production.

The ISO9001 standard encompasses all stages of a manufacturer’s workflow, from initial quoting and design review through material verification, process control, calibration, and final delivery.

Certified organizations are required to maintain documented procedures, conduct internal audits, train personnel, and monitor performance indicators such as defect rates, on-time delivery, and corrective actions. A detailed overview of these requirements is available through the ISO9001 quality management standard.

Unlike product certifications, ISO9001 doesn’t focus on what a company makes; it focuses on how it operates. Auditors evaluate whether the manufacturer’s processes are systematic, documented, and capable of producing consistent results over time.

For OEMs, this is crucial: it means a supplier’s reliability can be verified objectively, not just promised.

ISO9001 also emphasizes continuous improvement, requiring regular management reviews, feedback loops, and corrective-action tracking.

When issues occur, certified manufacturers are required to find the root cause, correct it, and update procedures so it doesn’t recur. This feedback culture is what separates compliant suppliers from those simply reacting to problems.

Ultimately, ISO9001 gives OEMs confidence that every fabricated enclosure, bracket, or chassis is produced with repeatability, accountability, and measurable control, key ingredients for long-term supplier partnerships.

Why OEMs Require ISO9001 in Fabrication

In industries where safety, precision, and compliance intersect, ISO9001 isn’t just a credential; it’s a risk-management tool.

OEMs in aerospace, automotive, defense, and medical sectors depend on hundreds of suppliers, often scattered across regions or even continents. Without standardized quality systems, maintaining traceability and process consistency would be impossible.

Certified metal fabricators follow defined procedures for everything from incoming material verification to final inspection.

Each operation, laser cutting, forming, welding, or assembly, has documented work instructions that must be followed, checked, and recorded.

This not only ensures dimensional accuracy and surface finish quality but also creates an auditable paper trail if issues arise later in the supply chain.

For OEM procurement leaders, that traceability provides real peace of mind. It confirms that every component can be traced back to its source, material lot, and inspection record, critical for regulatory compliance and customer assurance.

DureX Inc., a contract manufacturer based in Union, New Jersey, exemplifies this principle. As President Bob Denholtz explains, “Any good metal parts supplier should be able to help the OEM determine the most cost-effective tooling for their situation, but always within a controlled, documented process that ensures repeatable quality.”

DureX’s approach to process validation and inspection aligns directly with the preventive focus of ISO9001’s framework.

OEMs also require ISO9001 because it eliminates subjectivity in supplier selection. Instead of relying on reputation or anecdotal performance, purchasing teams can rely on measurable evidence of compliance.

The certification ensures that vendors maintain quality documentation, train their teams consistently, and perform regular audits, key components of dependable long-term relationships.

In practical terms, OEMs that source sheet metal fabrication in NJ or elsewhere use ISO certification as a filtering mechanism. It simplifies vetting, reduces supplier-related risk, and improves consistency across global supply chains.

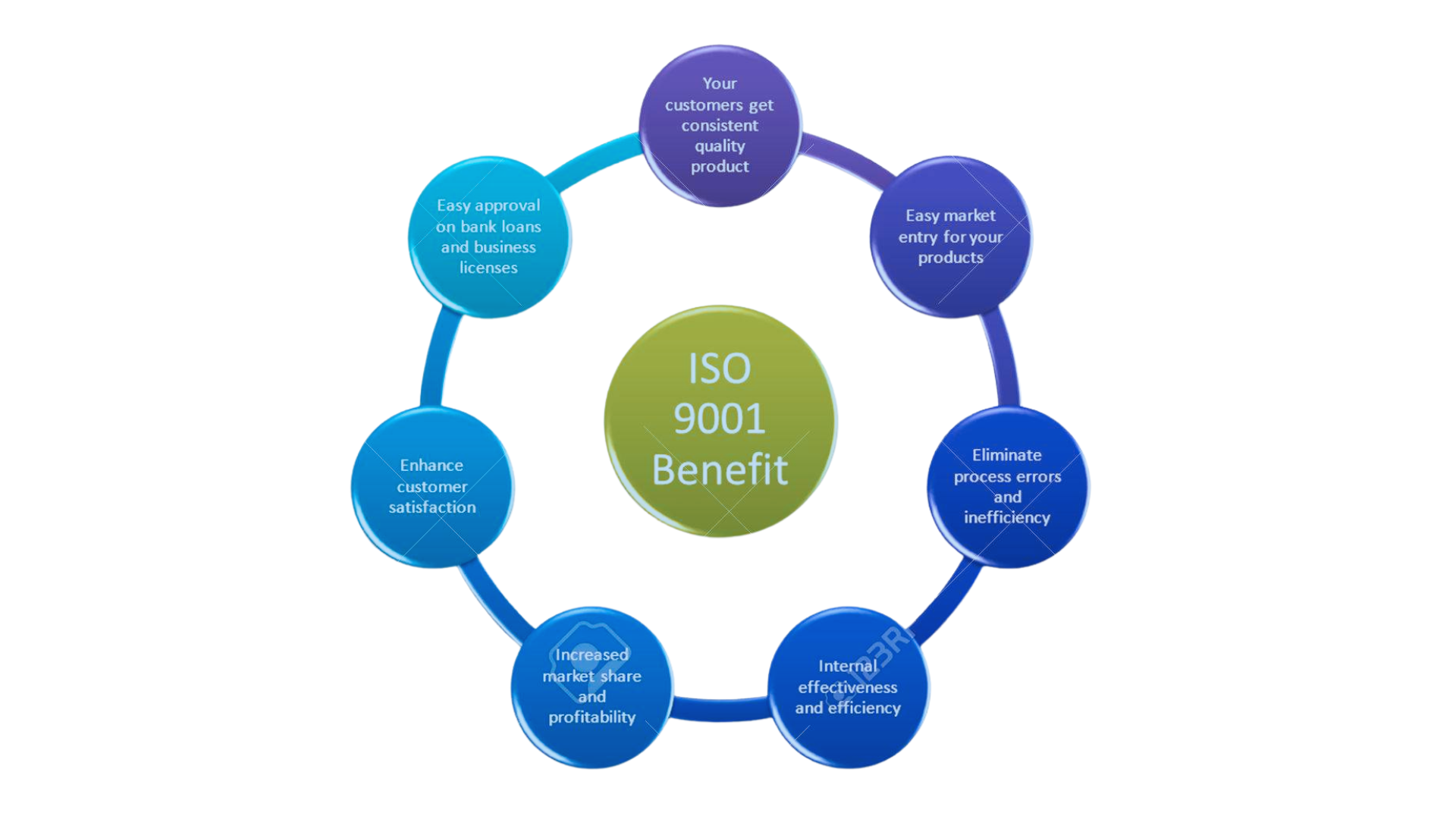

Benefits of ISO9001 for OEMs

For OEMs, working with an ISO-certified fabrication partner goes far beyond ticking a compliance box. It directly influences product reliability, lifecycle cost, and time to market. Certification signals a manufacturer’s ability to scale while maintaining precision, which is vital in multi-stage, high-volume environments.

Equally important, ISO9001 brings consistency across suppliers and production locations. It provides OEMs with measurable proof that the manufacturer follows standardized procedures for every process, cutting, forming, welding, machining, and assembly.

This continuity reduces the chance of variability between batches, shortens qualification cycles, and allows OEMs to maintain confidence even as programs grow more complex or global in scope.

Consistency and Repeatability

Every OEM values consistency. ISO9001 ensures that no matter who operates the laser cutter or press brake, the results will match prior production runs.

Documented procedures standardize setup, tooling, inspection, and packaging. This level of control minimizes variation and ensures that critical dimensions and finishes are met on every shipment.

Repeatability is particularly vital for industries like aerospace, where even a 0.1 mm deviation can affect performance.

Under an ISO-certified QMS, process parameters are recorded, monitored, and reviewed to detect and correct variation before it affects quality.

Fewer Defects and Less Rework

Defects don’t just waste material; they jeopardize schedules, budgets, and reputations. ISO9001 requires manufacturers to adopt preventive strategies through corrective-action processes and root-cause analysis.

Instead of reacting to non-conformances, certified suppliers track trends, identify systemic issues, and implement permanent fixes.

This proactive approach dramatically reduces scrap rates and ensures stable throughput. Over time, OEMs see lower warranty claims, fewer returns, and greater confidence in part reliability.

Supplier Accountability and Transparency

ISO9001 brings structure to communication between OEMs and fabricators. Certified manufacturers maintain detailed inspection records, calibration logs, and material certificates.

These documents make audits straightforward and help resolve issues quickly because data, not guesswork, guides the discussion.

Accountability also builds trust. OEMs know that their partner is monitored not only internally but by accredited third-party auditors who evaluate compliance annually.

Alignment with Global Compliance Standards

Today’s OEMs often operate across borders, assembling products from multiple continents. ISO9001 provides a common language of quality that simplifies global collaboration.

It assures a European aerospace client, for instance, that a component fabricated in New Jersey adheres to the same fundamental quality principles used across its global network.

A ThomasNet Insights report on quality management in manufacturing reinforces this point: organizations that work exclusively with ISO-certified suppliers report higher customer satisfaction and stronger long-term performance metrics.

Certification establishes a clear benchmark for supplier reliability and reduces administrative overhead from multiple audits.

DureX’s internal systems embody these benefits. With integrated inspection procedures and cross-departmental communication between fabrication, stamping, and CNC teams, the company achieves the kind of repeatable quality that ISO9001 demands, reinforcing confidence for OEM clients worldwide.

Industry Examples: Aerospace and Automotive Supply Chains

Few industries illustrate the importance of ISO9001 better than aerospace and automotive manufacturing. Both sectors depend on precision components, traceability, and predictable performance.

The difference between success and failure often lies in microns, and in the documentation that proves compliance.

In aerospace, ISO9001 forms the foundation for even stricter standards such as AS9100. Every step, from raw material certification to process validation, must be traceable.

If a component fails, investigators need to know exactly which machine, operator, and material lot were involved. Only suppliers with disciplined systems can provide that level of visibility.

In the automotive industry, where production volumes are massive and cost pressures relentless, ISO9001 offers stability.

Certified suppliers can sustain high throughput without compromising dimensional control, enabling just-in-time manufacturing models to function efficiently.

Even small deviations in a stamping die or welded bracket can halt assembly lines, so OEMs depend on suppliers who maintain rigorous process control.

According to Industrial Machinery Digest, DureX’s vertically integrated structure, offering sheet metal fabrication, stamping, and machining under one roof, allows OEMs to scale production without switching vendors.

This one-stop approach, managed through standardized procedures and in-house quality systems, reduces supplier complexity and aligns perfectly with ISO9001’s goal of process uniformity.

DureX has applied these same principles to real-world projects. When a client’s production scaled from hundreds to thousands of parts monthly, the company transitioned from soft tooling to hard tooling without disrupting delivery schedules or quality benchmarks.

That seamless process control exemplifies what ISO9001 is designed to protect: repeatable excellence through every stage of growth.

For OEMs seeking consistency across multiple manufacturing disciplines, from sheet metal fabrication to precision machining, ISO9001 certification assures that quality systems remain stable as production scales.

It establishes standardized controls that align design intent, process validation, and inspection practices across facilities.

This approach helps maintain dimensional accuracy and material performance throughout each phase of manufacturing, including advanced operations such as precision CNC machining in NJ

FAQs

Why is ISO9001 important in metal fabrication?

ISO9001 provides a structured, globally recognized framework that ensures every fabricated part meets defined quality and performance standards. It builds discipline into workflows, improves documentation, and requires continuous monitoring of critical metrics like defect rates and lead times. For OEMs, this means predictable performance and dependable outcomes on every project.

Do OEMs require ISO9001 certification?

Yes. Most OEMs, especially in regulated industries such as aerospace, medical devices, and automotive, require ISO9001 certification as a baseline. It’s not simply a preference; it’s a contractual requirement that ensures suppliers can demonstrate traceable, auditable quality management systems.

How does ISO9001 reduce risk for OEMs?

ISO9001 minimizes risk by mandating preventive quality measures, internal audits, and root-cause analysis. It enforces documentation at every step, ensuring that issues can be traced and corrected before they escalate. For OEMs, that means fewer surprises, fewer delays, and reduced liability exposure throughout the supply chain.

How does ISO9001 improve supplier communication and accountability?

The standard requires clear documentation of responsibilities, review processes, and corrective actions. This structure enhances communication between OEMs and fabricators by replacing assumptions with data. When quality issues occur, ISO9001 ensures that both sides work from the same information, inspection reports, calibration logs, and verified procedures, resulting in faster resolutions and stronger long-term partnerships.

What advantages do OEMs gain by partnering with ISO-certified fabricators?

ISO9001-certified partners offer measurable advantages: consistent part quality, lower scrap rates, smoother audits, and reduced administrative burden. Certified suppliers like DureX have proven systems for process control, training, and inspection, enabling OEMs to scale production confidently while maintaining compliance across global operations.

Why OEMs Shouldn’t Compromise on ISO9001

Partnering with non-certified fabricators might appear cost-effective initially, but it often introduces hidden risks: inconsistent production, undocumented deviations, or poor corrective-action systems. Over time, those risks translate into rework costs, missed deadlines, and reputational damage.

By contrast, ISO-certified manufacturers like DureX operate within a disciplined quality framework that ensures predictability from prototype to production. Each part, assembly, and process step is traceable, documented, and measurable. This transparency protects OEMs from downstream failures and reinforces confidence in the final product.

Moreover, ISO9001 supports the future of smart manufacturing. As the industry moves toward data-driven production and digital twins, the standard’s focus on documentation and traceability provides the ideal foundation. It bridges human expertise and automated analytics, ensuring that continuous improvement remains both measurable and repeatable.

For OEMs, ISO9001 isn’t just about meeting today’s expectations; it’s about building a supply chain capable of meeting tomorrow’s challenges. Choosing a certified partner means fewer variables, greater consistency, and a lasting assurance of quality excellence.

These principles are reflected in DureX’s ISO-certified operations, where integrated quality management supports consistent performance, compliance with customer requirements, and continuous improvement across all stages of custom sheet metal fabrication services.

ISO9001 in metal fabrication provides a standardized, auditable framework that ensures consistency, traceability, and continuous improvement. For OEMs, it mitigates supply-chain risk, enhances global trust, and guarantees that every component meets defined quality and compliance benchmarks. Certified manufacturers like DureX Inc. demonstrate how integrated quality systems translate directly into fewer defects, lower costs, and more reliable partnerships.